What are U-Cup Seals?

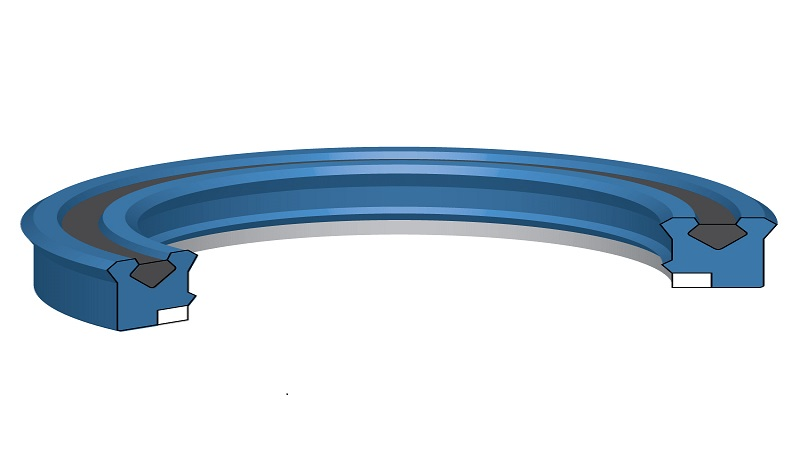

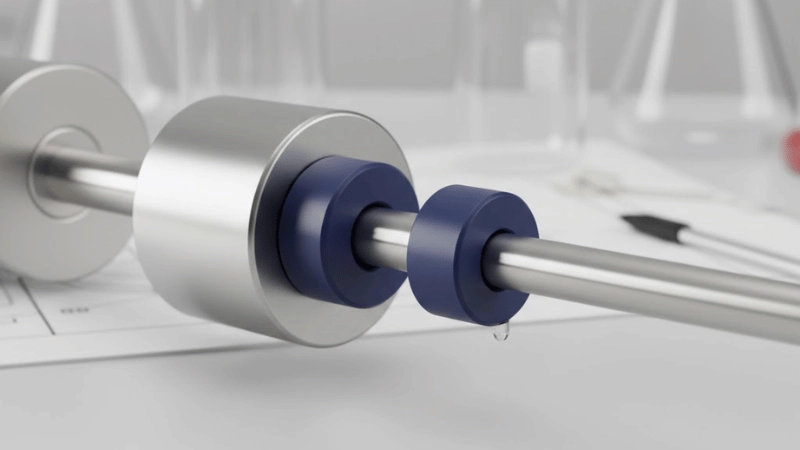

As the names indicate, U-Cup seals have a structure in the form of a “U” and consist of two lips: one on the exterior, which provides static sealing, and one on the interior, which provides dynamic sealing.

U-shaped lip seals demonstrate enhanced energizing effect under increasing pressure. The three most common variants are the standard U-Cup, Deep U-Cup, and Beveled lip U-Cup.

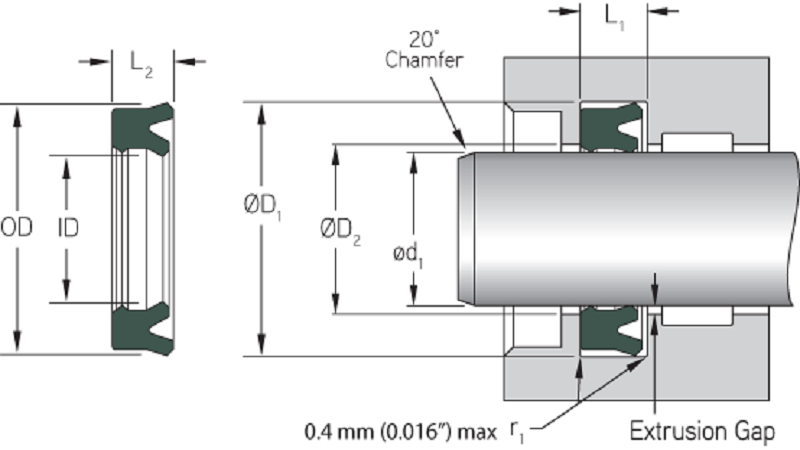

Standard U-cups maintain consistent height and cross-section, while Deep U-cups feature a higher height-to-width ratio. The Beveled lip U-cup (B-type) is distinguished by its unique beveled design.

Properly installed B-type symmetrical U-Cups can withstand pressures up to 5000 psi. This adaptable reciprocating seal is available in both unloaded and loaded configurations to suit different application requirements.

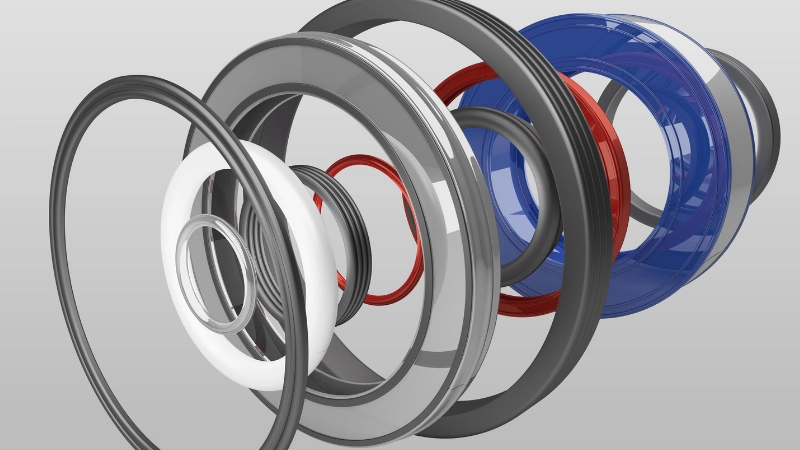

When referring to a device, the lack of an O-ring inside it is the meaning behind the word “unloaded.” However, the filled U-Cup, often called a Polypak, has an O-ring or a quad ring placed within the seal to provide even more robust sealing qualities.

In addition, these rings can increase in size.

It is common practice to refer to a loaded U-Cup as a Polypak after its use. U-Cups excel in circumstances that call for a low breakaway pressure since they do not rely on initial compression to create a seal.

This makes them ideal for use in these kinds of circumstances.

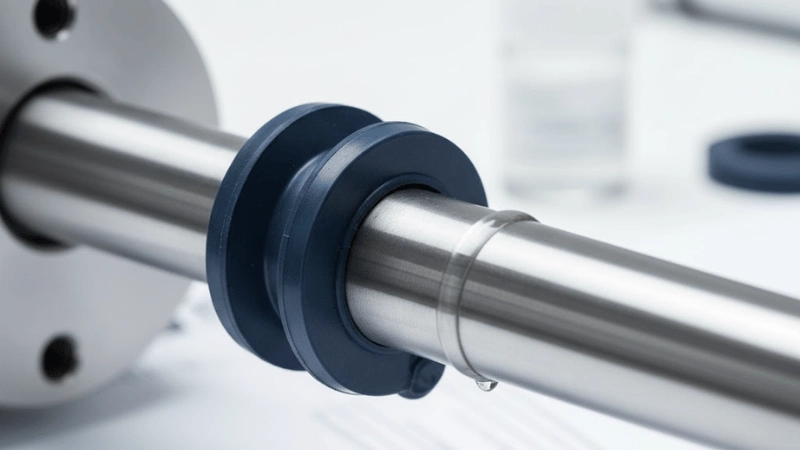

Depending on the situation, u-cups may be employed for piston or rod sealing. They often seal the rod or piston when utilized in linear applications.

The very condensed gland space required for U-Cups, which must be at least 110% of the height of the seal being used, is one of the primary reasons for the product’s widespread acceptance.

The expansion of the sealing material in response to a rise in temperature and the effects of the system fluids necessitate this extra space.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What are U-cup Seals Used for?

U-cup seals have a place in several sectors for dynamic applications, although they are most often used in hydraulic and pneumatic settings. Some of them are as follows:

- Purification of water

- Oil & gas sectors

- Petroleum products

- Heavy engineering

- Agricultural production

- Filling machinery

- Auto components

- Pipeline projects

The Different Types of U-cup Seals

U-cups are very adaptable and can be utilized for various applications, including the sealing of rods and pistons. As was previously said, there are a variety of primary categories and sub-types of U-cups available to choose from.

These can also impact the seal’s life expectancy.

- Loaded U-Cups

Applications involving emotional reciprocation were the primary focus of the design of loaded U-cups. Because of the O-rings loading, this seal is excellent for low-pressure rods and pistons.

The loading lips are subjected to increasing force when using loaded U-cups as the system pressure rises. The sealing force automatically mitigates the additional pressure, ensuring a positive seal is maintained.

Unloaded Urethane U-Cups

The unloaded U-cup shape of the urethane makes for a tremendous heavy-duty seal in either static or dynamic settings, and it can be used with either pistons or rods.

As a result, the unloaded urethane U-cup is often referred to as a Disogrin U-cup amongst industry professionals.

Homogeneous U-Cups

Homogenous U-cups are often used in low-pressure applications that might benefit from a seal with lower frictional resistance. However, pneumatic applications are where you’ll most often see them utilized.

Z-Seal U-Cups

Z-seals are a special kind of squeezing seal that finds their most common usage in applications involving very heavy rods.

Z-seals outperform alternative lip seals in terms of their scalability, compaction set, and improved anti-extrusion qualities. In addition, the sealing lip can do its job as long as there isn’t too much pressure trying to get in.

Spring Energized U-Cups

Spring-energized U-cups are a kind of seal that is often constructed of plastic and includes a metal spring as part of its construction.

Seal lips are loaded by a spring and pressed against their matching hardware to create a seal that can stretch with the hardware and maintain its seal.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

The Benefits of Using U-cup Seals

A U-cup seal comprises two sealing lips pushed closer to the wall when the pressure within the cup increases. A key benefit of U-cup seals is that their effectiveness improves with increasing fluid pressure since the force on the sealing lips rises proportionally.

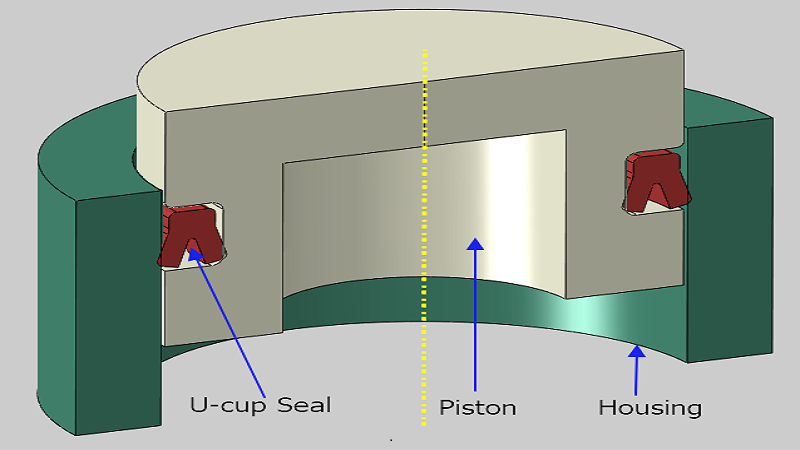

The piston, housing, and u-cup are all rotationally symmetrical components of the model. The U-cup is housed inside the gland, with a cutout in the piston.

This is challenging because it incorporates many different nonlinearities, including the material’s and geometry’s nonlinearities and the contact between numerous components.

An axisymmetric model is used to do the analysis on this issue since both the dimensions and the loads are axisymmetric. This results in a considerable decrease in the amount of time required for computation.

How to Choose the Right U-Cup Seal for Your Needs?

Several factors, such as fundamental requirements and design components, must be considered when deciding which U-cup seal best suits a particular application.

Therefore, we recommend speaking with a professional salesperson so they can assist you with product recommendations tailored to your specific use case.

There are a few things to keep in mind while picking out a U-cup seal, and they are as follows:

Fluid Materials

U-cup seals can be utilized in various hydraulic applications, but it’s necessary to consider the fluid type before purchasing. This means the fluid or chemicals will dictate the kind of seal used with it.

Support Materials

The kind of seal and material that will be best appropriate for a particular application will depend on factors such as the maximum and minimum temperature ranges of the fluid being sealed and the seal itself.

Systemic Strain

The sealing compound that is used will determine the level of pressure that the seal material can withstand.

Prolonged Blistering and Lip Squeezing

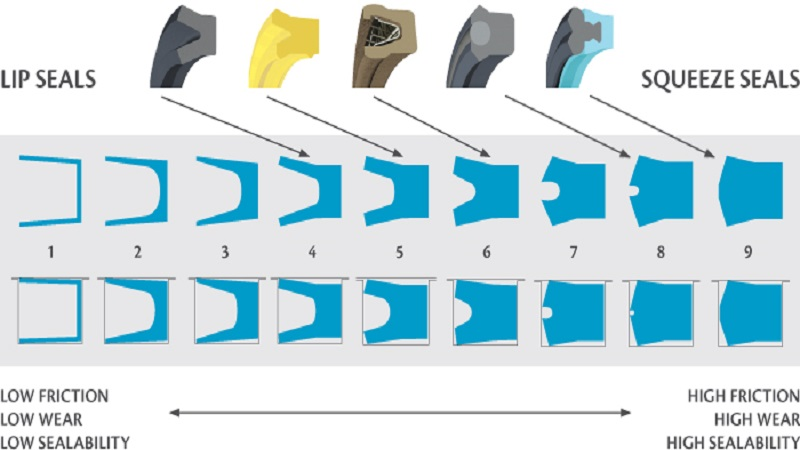

Different applications call for different friction, wear, and sealability levels in the lip seals and squeezing seals.

Gland Sizing and Alterations

Since U-cup seals are generally built to fit the layouts of the glands they are meant to seal, assessing how well a U-cup seal will fit either a new or an existing gland is essential.

Installation

There is a wide selection of U-cup seals available, and although some may be installed with little effort, others may need more of your time and attention.

The installation of a U-cup seal will be performed differently for various reasons, including the seal’s size, shape, material, and specific function.

The Seal’s Average Lifespan

How long a seal may be anticipated to live depends on factors like its genetic makeup, species, and environment.

The seal’s predicted lifetime is affected by various factors, including the quantity of strokes, the pressure applied, the kind of fluid being sealed, the exterior polish, the repetition rate, and the speed.

Value and Availability

The ideal U-cup seal will be able to increase output cost-efficient and reliable manner during its working lifespan.

Facts About U-cup Seals

At more significant pressures, a U-cup seal’s sealing lips are subjected to a force that is proportionate to the pressure; as a result, the U-cup seal transforms into a more effective sealing element.

The U-cup is ideal for hydraulic and pneumatic systems because of its symmetrical design.

Primary seals from NBR are utilized for systems with pressures up to 15 MPa. TPU can withstand working pressures of up to 40 MPa, making it an ideal material for U-cup seals.

Due to the outstanding abrasion resistance provided by TPU, these seals are suited for primary and secondary seals.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

U-cups are an essential element in the overall life of the seal on any piston or cylinder. They may seem like spheres, but their U-shaped construction keeps the pneumatic or hydraulic cylinder secure.

With its one-way seal, the U-primary cup is ideal for low-pressure applications involving rod or piston cylinders. Because of its loader configuration, the lip seal is squeezed to produce the appropriate sealing force. Nevertheless, it functions admirably under circumstances of extremely low or very high pressure as well as vacuum.

Turn Ideas into Products Faster with Hongju!

U-cup sealing solutions are one of the seals and gaskets that Hongju specializes in manufacturing. Enjoy 3–5 day rapid prototyping, low minimums, and 20 years of silicone expertise.

Contact us today! Let’s create your next high-quality silicone product!