Polypropylene fiber has become an essential material in modern construction for enhancing concrete strength and durability. Known for its versatility and cost-effectiveness, this synthetic fibre improves crack resistance and extends the lifespan of concrete structures.

In this article, we explore its history, manufacturing process, key applications, and how to choose the right PP fiber for your project.

What is Polypropylene Fiber?

Polypropylene fiber is a synthetic fiber whose specific mechanical properties make it the most suitable material in the construction industry, especially concerning the concrete surface. This versatile synthetic fiber is made from the thermoplastic polymer polypropylene.

Here are some mechanical characteristics of polypropylene fibers that make them ideal materials to blend with concrete.

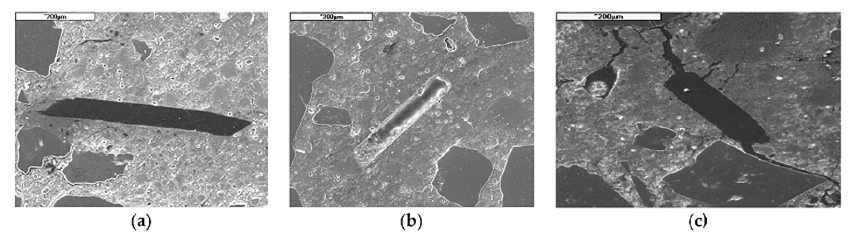

Crack Resistance: Polypropylene fiber effectively suppresses early-stage cracking in concrete. By controlling micro-crack formation, it enhances structural integrity and prevents minor flaws from escalating into major defects over time.

Durability: Polypropylene fiber improves concrete’s chemical resistance, enabling it to withstand harsh environments including freeze-thaw cycles and corrosive exposure. This significantly extends the service life of concrete structures.

Impact Resistance: In high-traffic areas requiring improved mechanical performance, polypropylene fibers increase impact resistance. The fiber-reinforced composite better withstands heavy loads and dynamic stresses.

Shrinkage Control: The incorporation of polypropylene fiber effectively reduces shrinkage cracks during concrete curing and drying. This helps maintain both structural and aesthetic integrity over the long term.

Corrosion Resistance: As a non-corrosive material, polypropylene fiber provides durable reinforcement without rust-related degradation. This ensures long-term structural reliability without the risk of metallic corrosion.

Permeability Reduction: Polypropylene fiber modifies the pore structure of concrete, resulting in significantly reduced permeability. This enhances resistance to water infiltration, making it particularly valuable in marine and hydraulic engineering.

Fire Resistance: The inherent fire-resistant properties of polypropylene fiber help concrete meet stricter fire safety standards, making it a strategic choice for buildings requiring enhanced fire performance.

Send your inquiry for prompt quotations!

Historical Context of Polypropylene Fiber

It’s time to dig into the history of fiber to understand the modern and historical context of polypropylene fiber So, let’s get into that.

Traditional fiber reinforcement in the concrete mixture

According to Wikipedia, If you check the history, you will find out that fibers have been used to reinforce concretes from ancient times.

A quick look at history records depicts that contractors used to incorporate different materials for construction such as animal hair, and straws.

Even asbestos fibers were used to boost the durability and strength of a structure in the 1900s.

However, health risks associated with asbestos pushed experts to look for alternative fibers that can boost the compressive strength of concrete without putting anyone at health risk.

Emergence of Synthetic Fibers

Scientific research in the 1960s introduced polypropylene fiber as a novel material in construction, a field then dominated by steel fibers prized for their high tensile strength and robust engineering performance.

The mid-20th century saw synthetic fibers revolutionize construction materials. While materials like nylon and polyethylene were also widely adopted, polypropylene gradually stood out.

Among various synthetic fibers, polypropylene gained widespread popularity due to its superior mechanical properties, including corrosion resistance, impact strength, high durability, and consistent performance.

Evolution of Polypropylene Fiber Usage

In the 1960s–1970s, commercial polypropylene fibers were first developed to reinforce concrete, primarily aimed at reducing plastic shrinkage during curing.

By the 1990s, these fibers gained popularity in structural applications, notably enhancing the impact resistance and durability of industrial floors and pavements.

From the 2000s to today, ongoing research has expanded the versatility of fiber-reinforced concrete. A range of polypropylene fiber types is now available, allowing customization to meet specific project needs, while steel reinforcement remains common in high-strength applications.

Send your inquiry for prompt quotations!

Manufacturing Process of Polypropylene Fiber

It’s time to explore the step-by-step manufacturing process of Polypropylene Fibre.

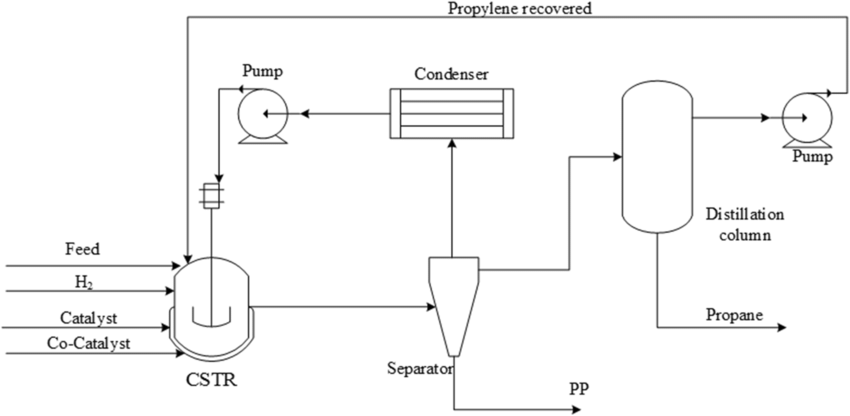

Step One Polymerization: It all begins with the polymerization of propylene monomers. This process is done by utilizing Ziegler-Natta catalysts or metallocene catalysts.

The purpose of this catalyst is to speed up the boding of polypropylene monomers to produce long chains of polypropylene molecules.

Step Two Extrusion: Polypropylene polymers are melted and extruded using a spinneret in this step. The melted polymer is forced through the spinneret. As a result, continuous filaments are formed. Initially, these filaments are in a molten state.

Step Three Cooling and Solidification: The cooling process begins when molten filaments pass through air cooling and get a quenching bath. The purpose of cooling is to solidify the fibers. This solidification gives the fiber a solid and stable form.

Step Four Drawing: The solid filaments are now drawn through a series of heated godets. This drawing aims to improve the alignment of polymer chains and boost their orientations and tensile strength.

Step Five Cutting: After drawing the filaments, the cutting process begins. Filaments are cut into either short fiber lengths or continuous filaments. Cutting of fibers ultimately depends on their applications.

Step Six Packaging: The finished polypropylene fibers are packed into different forms and then distributed to manufacturers of various products.

Applications of Polypropylene Fiber in Modern Construction

Here are the most common uses of Polypropylene fibre reinforced concrete in the modern construction industry.

1. Concrete Reinforcement

These fibers are commonly mixed with create to reduce the formation and propagation of cracks. They effectively control plastic shrinkage cracking and reduce all the effects of temperature-related stresses.

Due to their impact resistance properties, they are commonly used to produce bridge decks, pavements, and industrial floors. They reduce the risk of surface damage due to heavy traffic, load, or impact.

Polypropylene fibre-reinforced concrete is often added to Mortar and Render Systems because it boosts up tensile and flexural strength—the durability properties of wall coating increase due to polypropylene fibers.

2. Geotechnical Engineering

Polypropylene fibers are mixed with soils to improve their load-bearing capacity. They also increase soil cohesion.

Besides these, steel and polypropylene fibers are used to create geotextiles and erosion control blankets, which effectively prevent soil erosion in riverbanks and slopes.

3. Tunnel and Mine Construction

These fibers are often added to concrete and shotcrete mixes during underground construction. They are robust building materials for mine support concrete structures and tunnel lining due to their exceptionally high tensile strength.

4. Concrete Pipes and Precast Products

These fibers increase the toughness of concrete pipes and precast concrete products. When fibers are added to production, it increases the resistance against the cracking of fresh concrete.

5. Bridge Decks

When contractors need to create a bridge in areas prone to the freeze-thaw cycle, it becomes essential to add polypropylene fibers as they add strength to the structure and enhance the crack and impact resistance of concrete.

6. Residential and Commercial Construction

When constructing solid and stable floors, expert engineers always add polypropylene fiber reinforced concrete to the building material plan. They improve the durability of a floor surface and increase its resistance against heavy traffic.

Send your inquiry for prompt quotations!

Advantages of Polypropylene Fiber Reinforced Concrete

Here are some benefits you can get by reinforcing concrete with Polypropylene

1. Reducing Spalling Risk in Concrete with Polypropylene Fibers

Whenever concrete is exposed to extreme temperatures, the water inside it turns into steam. As a result, spalling and loss of structural integrity happen.

When polypropylene fibers are mixed with concrete, these fibers melt and design a route for steam to escape. Water absorption reduces.

The fire-resistance properties of Polypropylene fiber reinforced concrete makes them an ideal reinforcement building material for constructing tunnels, bridges, and other fire-resistant concrete structures.

2. Utilizing Polypropylene Fiber for Sustainable Structural Reinforcement

Every contractor wants to create a sustainable structure. Thanks to polypropylene fibers, the durability of concrete is boosted. This structure requires less maintenance and repairs.

Minimizing resource consumption and the long lifespan of structure contribute to overall sustainability while reducing environmental impact.

3. Enhancing Concrete Strength and Durability with Polypropylene Fibers

These fibers improve the mechanical properties of concrete, such as flexural strength, tensile strength, and impact resistance. This reinforcement leads to durable and long-lasting concrete structures.

Therefore, it is an ideal mixture to create pavements and industrial floors.

4. Controlling Shrinkage and Crack Formation in Concrete using Polypropylene Fibers

Polypropylene fibers reinforced concrete addresses the biggest constructional challenge of concrete, aka cracks, formed during cure and over time. When contractors support concrete with Polypropylene fibers, they reduce cracking- both plastic and drying shrinkage.

You can improve structural aesthetics through these fibers.

5. Improving Impact Resistance and Fire Resistance of Concrete with Polypropylene Fibers

Polypropylene fibers can improve fire resistance and impact resistance properties of concrete. These fibers are commonly used in heavy traffic or heavy load areas due to their load-carrying capacity.

Many commercial floors, military bunkers, and bridge decks are created with polypropylene fibers enforced concrete. The purpose is to reduce impact and prevent fire hazards.

Choosing the Right Polypropylene Fibers for Your Needs

It would be best if you chose the right Polypropylene fiber by looking into various factors such as:

1. Application Requirements

What’s the primary purpose you want to achieve from polypropylene fiber in your project? These fibers let you control cracks, improve fire resistance, and boost durability. Choose a fiber as per your specific goal.

2. Fiber Type

You can find different types of Polypropylene fibers. Monofilament/Single strand is ideal for a construction project where you want to control shrinkage cracking. This filament offers better dispersion in the mix.

Conversely, using multifilament to improve structural reinforcement and impact resistance would be best.

3. Fiber Geometry and Length

Another thing to consider when choosing the suitable fiber for the construction is the fiber length. Short fibers are effective in controlling plastic shrinkage cracking.

But when a project requires you to boost structural reinforcements, then long fibers are suitable.

4. Dosage Rate

You can find polypropylene fibers in different dosage ranges, ranging from 0.1% to 2% by concrete mix volume. You will pick a specific dosage rate as per your project requirements.

5. Compliance with Standards

ASTM International has set specific standards for fibers used for the strength of plain concrete. So, when you are going to use these fibers in a particular project, make sure they meet relevant industry standards and guidelines.

6. Compatibility

You need to mix many additives, aggregates, lightweight aggregate concrete, and other materials during construction. Before picking a specific fiber, double-check its compatibility with other materials.

It’s because any compatibility issue will affect the overall performance of concrete.

7. Consultation

When unsure about the type of PP Fibres, it’s good to seek advice from experts such as structural engineers or concrete contractors.

Send your inquiry for prompt quotations!

Conclusion

Polypropylene fiber transforms modern concrete by significantly enhancing durability, strength, and sustainability. It reduces cracking and spalling risks, even under high temperatures, while improving structural integrity in residential and infrastructure projects.

An efficient, engineered solution for building stronger and greener with fiber-reinforced concrete.

Unlock the Full Potential of Polypropylene Fibers with Hongju!

Do you want to elevate your construction project? Or are you seeking stronger, safer, and more resilient plain concrete structures?

No matter what you want, Hongju‘s experts are here to help. We will guide you on how you can control cracks by making the right choice of PPF.

Contact Now! Our expert advice and guidance will let you enjoy long-term sustainability for your next construction project.

FAQs

1. What is the main purpose of adding polypropylene fiber to concrete?

It enhances concrete’s toughness, reduces cracking, and improves resistance to impact and shrinkage.

2. How does polypropylene fiber improve concrete performance?

The fibers distribute stress evenly, preventing micro-cracks and extending the structure’s service life.

3. Is polypropylene fiber suitable for all types of construction projects?

Yes, it’s widely used in floors, pavements, tunnels, and precast structures for both residential and industrial applications.

4. How do I choose the right polypropylene fiber for my project?

Select fiber length and type based on your mix design, load requirements, and desired surface finish for optimal results.