Thermoplastic elastomer (TPE) is somewhat distinct as a common name made for soft, flexible plastic materials that you may not know you meet every day. And many consumers really want to know: Is TPE toxic?

Quite simply, TPE is considered non-toxic and safe. We’ll explore what TPE is made of, how it is regarded as safe, and how you can ensure that the TPE products that you purchase are safe.

What Constitutes TPE Composition?

Thermoplastic Elastomer is not a single plastic; TPE is a family of materials that mixes two types of polymers: One part provides rubber-like flexibility, while the other provides easy processing like a normal thermoplastic.

They get soft, elastic parts without using classic rubber processes, which are slower and harder to recycle.

There are various blends of base materials that make the TPE. The most common one among those is SEBS as a styrene block copolymer, which happens to be a very clean and stable one.

Why TPE Is Generally Non-Toxic?

When a person thinks about toxicity regarding plastics, the first thing that comes to mind is BPA, phthalates, heavy metals, or latex proteins that can induce allergies.

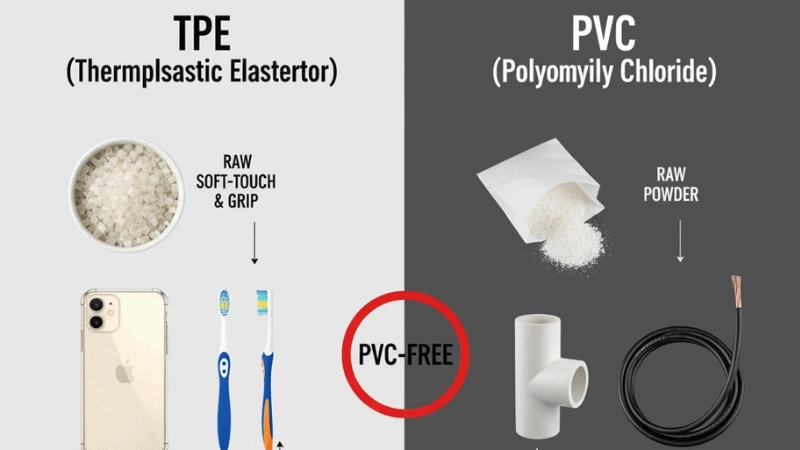

Another major point now is that TPEs are mostly free from PVC. PVC is a polymer containing chlorine that develops poisonous gases such as hydrogen chloride when burnt or overheated badly.

Hence, TPE does not possess any chlorine and, thus, is cleaner in that sense.

Safety Standards and Certification of TPE

The term “TPE or Silicone” does not automatically make it safe; the safety has to be demonstrated through rigorous testing and compliance with relevant international standards and regulations.

FDA approval

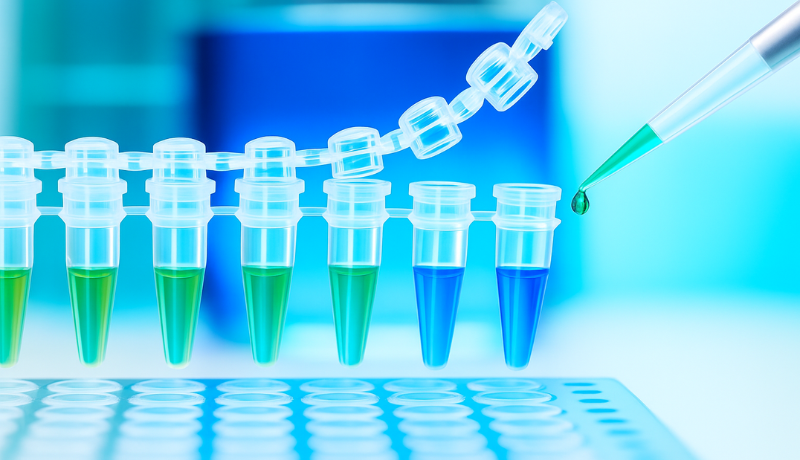

FDA-compliant grades of TPE are tested to ensure they do not transfer unsafe chemicals to food or the human body. These materials are used for applications such as baby products, food seals, medical tubing, and parts for syringes.

RoHS

RoHS-compliant TPEs are regulated for heavy metals as well as some toxic flame retardants, such as lead, cadmium, and mercury.

This is especially important for parts used in the electrical and electronics industry, such as cables and connectors.

EU REACH Certification

REACH-compliant TPE follows strict European legislation on chemicals and substances of very high concern (SVHCs). It is an indication that the supplier has assessed and controlled chemical risk during the material formulation.

ASTM Standards

ASTM standards provide methods of testing and performance characteristics for TPE, including mechanical strength, durability, and in some cases, biocompatibility.

ASTM standards provide engineers with information to compare materials and design safe and reliable parts.

These certifications serve as evidence that the TPE has been tested for safety, legality, and performance.

Can TPE Cause Allergic Reactions?

No material is free from hazardous effects on an individual. Rarely, TPE itself may cause allergic reactions on the skin of certain individuals.

Usually, the reaction is not caused by the parent polymer itself but by something added to it, e.g., color pigments, process aids, production aids, or some amount of impurities.

Common symptoms of mild reactions include redness of the skin, rash, itching, or slight swelling in the area where the product has been in contact with the skin for extended periods.

These signs usually go away shortly after the product is removed. More serious reactions, which are rare, should always be assessed by a healthcare professional.

In the interest of maximizing consumer safety, manufacturers of products intended for babies, medical uses, or prolonged skin contact usually prefer special medical-grade or hypoallergenic TPE.

Is TPE Safe for Food and Medical Applications?

TPE can be an extremely safe candidate for food and medical applications if the right grade is chosen and all applicable regulations are complied with. Generally, TPE is chemically inert, which means that it is not prone to interacting with food or body fluids.

The food industry utilizes silicone elastomer and TPE for seals and gaskets for bottle caps, jars, and containers. It provides soft and tight seals that prevent the escape of liquids and gases.

When these materials are allowed for food contact, migration tests have verified that they would withstand contact with various foods, including fats, acids, and alcohols.

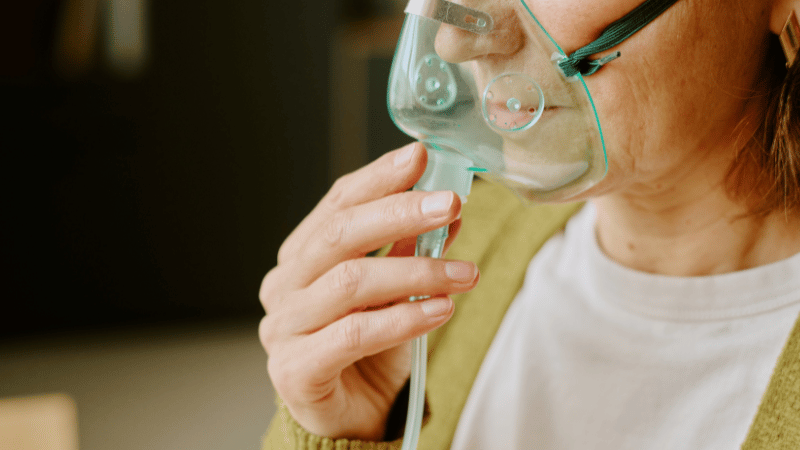

The medical industry also uses TPE in parts such as tubing, syringe plunger tips, seals for respiratory masks, and flexible components in wearable devices. The process for this type of molding is injection molding.

Here, depending on the grade, the materials should withstand sterilization techniques such as autoclaving, gamma radiation, or ethylene oxide sterilization.

Biocompatibility testing assesses whether the TPE will cause irritation or sensitization or be toxic to cells and tissues. The SEBS-based TPE is favored for this purpose because of its high cleanliness and stability.

TPE vs Other Materials: Toxicity Comparison

Let’s compare TPE with other materials to assess the toxicity profile:

| Material | Main Concern | Overall Safety | Typical Uses |

|---|---|---|---|

| TPE | Certified grades are usually free from BPA, phthalates, latex, and heavy metals. | High – generally non-toxic under normal use, especially with FDA/RoHS/REACH compliance. | Grips, seals, toys, cables, medical parts, food-contact components. |

| PVC | May use phthalate plasticizers and some chlorine-based additives; concerns if poorly controlled. | Low–Medium – safety depends strongly on formulation and quality control. | Low-cost toys, hoses, flooring, and cable insulation. |

| Silicone | Very few concerns; issues mostly with low-grade or heavily filled products. | Very High – highly inert and trusted for sensitive uses. | Bakeware, baby nipples, medical components, high-temperature seals. |

| Rubber | Natural rubber can trigger latex allergies; some additives may create unwanted by-products. | Medium – safe when additives and curing agents are well controlled. | Tires, gloves, seals, industrial hoses, elastic parts. |

Guideline to Choose Safe TPE Products

The safety of TPE depends on which TPE you are looking for, since there are many types on the market. There are a few good principles that should be observed to protect the customer and the brand.

The first one is to always buy from those manufacturers who can provide bona fide documents. This means having complete technical datasheets and Safety Data Sheets.

Factories should also be able to show that they operate under stable quality systems, such as ISO certifications.

Secondly, avoid TPE grades that are really cheap and not well-known. These could be from recycled materials from unpredictable sources, plasticizers that are cheaper, or possibly colorants that do not comply with RoHS or REACH.

Thirdly, ask for the test results of compression molding and certificates corresponding to your application case. If your product will be in food contact, it should have evidence for food contact compliance.

Regarding electronics, there should be RoHS compliance. For toys, certain EN or ASTM toy standards are applicable.

TPE on Environment and Health Safety

From an environmental viewpoint, TPE holds several advantages over traditional rubber and some plastics. The emissions created during normal processing and use are rather mild.

Since there is no chlorine in the polymer chain, TPE and polyurethane used in food-gaskets do not generate the kinds of corrosive gases that can come from PVC when burnt or overheated.

This notion is safer for the workers in the industry and maintains good air quality in confined spaces like automobiles and houses.

Another positive is the low release of VOCs. Many TPE formulations are modernly designed to meet stringent low-odor and low-VOC criteria.

Conclusion

TPE is the new-age thermoplastic elastomeric rubber, which gives rubber-like softness but retains the processability of plastics.

If well-manufactured and appropriately certified, it is generally non-toxic, free from other common harmful substances, and stable in everyday use.

Partner with Hongjusilicone for Safe, High-Performance TPE

Choose Hongju Silicone for certified, non-toxic TPE solutions tailored to your industry. We offer super-fast CNC prototyping (3-5 working days), flexible low MOQ, and the expertise of decades in TPE formulation and design.

Are you ready to step up your products with safer-more intelligent materials?

Contact Hongju Silicone today for a personalized TPE quotation.

FAQs

Q1: Is TPE toxic or harmful to touch?

Under normal conditions, TPE is not toxic to touch and is safe for skin contact; very sensitive users should prefer hypoallergenic or medical-grade TPE and avoid unknown low-quality products.

Q2: Can TPE be used for baby or food products?

Yes, many TPE grades are designed for baby and food contact, but you must ensure the specific grade has proper approvals, like FDA and related test reports.

Q3: Does TPE release harmful gases when heated?

At recommended processing and use temperatures, TPE does not release harmful gases in significant amounts, but if overheated or burned, it can decompose and produce smoke like any plastic.

Q4: Is TPE safer than PVC?

In many applications, TPE is safer than PVC because it avoids chlorine chemistry and usually does not require phthalate plasticizers or heavy-metal stabilizers.