While selecting any material, it is essential to check its electrical conductivity. Testing electrical conductivity ensures optimal performance by verifying that the selected material meets the requirements. Silicone rubber is a commonly used material. Read this guide to get an idea of the electrical properties of silicone and the benefits of conductive silicone.

Is Silicone Conductive or an Electrical Insulator?

The question of does silicone conducts electricity well cannot be answered in a simple yes or no. The type of silicon, additives used, and the applications determine whether silicone is a conductor or an insulator.

Silicone in its original form is non-conductive, meaning it does not allow electrical currents to flow through it. Silicone is composed of flexible polymers and oxygen-silicon bonds. This strong bonding does not let electrons move through them, thus making silicone non-conductive.

With non-conductive characteristics, regular silicone is perfect for use in electrical insulation. It is also used in cable coatings, electronic component sealing, and protective equipment.

In case you want to make silicone conductive, then you need to modify it by adding some additives. Fillers like carbon black, silver, or nickel form conductive paths within the material. Thus making silicone conductive. The conductive silicone is used in EMI/ESD shielding, keypads, and medical electrodes.

A comparison of conductivity in common materials is given in the table below. This table will help electrical engineers in finding the answer to does silicon conducts electricity better than copper or not.

| Material | Electrical Conductivity (S/m) | Conductivity Type | Notes |

|---|---|---|---|

| Copper | ~5.96 × 10⁷ | Excellent conductor | Standard for high conductivity. |

| Aluminum | ~3.5 × 10⁷ | Good conductor | Lightweight alternative to copper. |

| Gold | ~4.1 × 10⁷ | Excellent conductor | Corrosion-resistant, used in electronics. |

| Carbon (graphite) | ~1 × 10⁴ – 3 × 10⁵ | Semi-conductor/conductor | Conductivity depends on crystal structure. |

| Silicone rubber | ~1 × 10⁻¹⁴ (pure form) | Insulator | Conductive only when filled with metal/carbon. |

| Glass | ~1 × 10⁻¹⁰ or less | Insulator | Very low conductivity, except when heated. |

Does Wet or Liquid Silicone Conduct Electricity?

Wet silicon has moisture on its surface and is ideally used in outdoor applications. Liquid silicone is not cured and is used in sealing applications. Both the wet and liquid silicone have excellent sealing properties and are flexible.

Owing to the properties of wet and liquid silicone, the question of whether wet silicone conducts electricity arises. The answer to this question is simple. Wet silicon is non-conductive; the moisture on the surface does not allow the electric current to pass.

Only if the water on the surface contains salt or contaminants is a conductive path created. However, the conductivity in such a conductive path is low.

Now, to answer the question, does silicon conduct electricity when liquid or not? We can say that liquid silicon in its non-cured form is also non-conductive. However, if you have modified the liquid silicon with fillers, then it is conductive.

Silicone as an Electrical Insulator: Properties and Uses

Being an electrical insulator, silicone is used for insulation in different industries. Silicone resists the flow of electric current, thus preventing short circuits. This is the reason behind the popular use of silicone rubber in protecting electronics and power systems.

Silicone can stay stable even when exposed to extremely low or high temperatures. This is because silicone has high dielectric strength and resists electrical breakdown. Non-conductive silicone rubber is used in cable jackets, potting compounds, and wire insulation.

Additionally, silicone is flexible, chemically stable, and moisture resistant. This is the reason why it performs well in harsh or wet environments.

Medical equipment, automotive wiring, and aerospace seals use silicone for durable electrical insulation.

How to Make Conductive Silicone: Methods & Materials

As we know that silicone can be made conductive by adding certain additives. Fillers like silver, nickel, and carbon black create pathways within the silicone that allow electric current to flow.

The process of making conductive silicone began with uncured silicone in liquid form. The fillers are then added to the liquid silicone and mixed. The mixture is then cured using heat or a catalyst and is shaped as desired.

Note that the amount and type of filler added to the mixture depend upon the level of conductivity required. By adjusting the filler concentration, product designers can alter the conductivity level. Doing this does not compromise the durability and flexibility of silicone at all.

Lower filler content creates moderate silicone conductivity, which is ideal for EMI shielding. Whereas higher filler content creates a higher conductivity and is used in cases when better electric current flow is needed.

Conductive silicone is used in ESD-safe keyboards, medical electrodes, gaskets, and seals. It is also used where metals cannot be used due to weight, flexibility, or corrosion risk.

Top Benefits of Conductive Silicone in Electrical Applications

Many engineers keep on finding answers to does silicon conducts electricity well or not. It is important to note that in the pure form, silicon does not conduct electricity. However, once modified, silicone conducts electricity and is beneficial in several electrical applications.

One of the benefits of conductive silicone in electrical applications is in EMI/ESD protection. Conductive silicone can protect sensitive electronic devices from electromagnetic interference and electrostatic discharge. Thus, it is useful in aerospace, medical devices, and electronics.

The other benefit of conductive silicone is that it is flexible, durable, and heat-resistant. All these characteristics make this type of rubber ideal for use in seals, gaskets, and circuit connections.

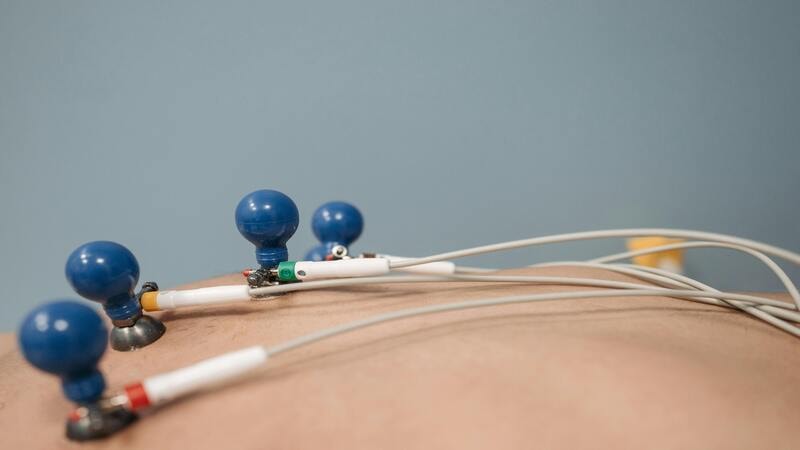

The medical industry uses conductive silicone in electrodes, wearable sensors, and diagnostic equipment. The reason behind this is that it is biocompatible, reliable, and resistant to moisture and chemicals.

Applications Of Conductive Silicone Across Industries

Conductive silicone is widely used across industries. Some of the common applications of conductive silicone are outlined below:

Electronics

In electronics, conductive silicone rubber is used in EMI shielding and heat transfer components.

Quick Fact: Many people wonder if silicon conducts electricity at room temperature or not. Well, in pure silicon, conductivity at room temperature is limited.

Medical

Medical-grade silicone, the conductive one, is used in medical devices and electrodes.

Aerospace/Military

In aerospace, seals that are subject to harsh environments use conductive silicone.

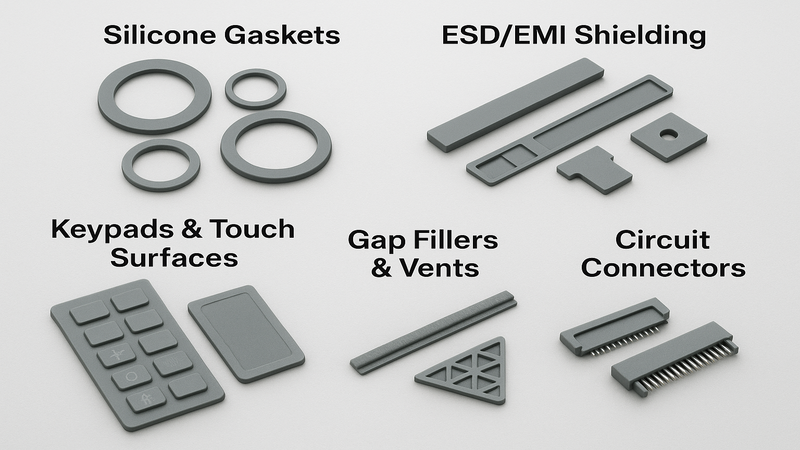

Common Parts Made from Conductive Silicone

Some of the common parts made utilising conductive silicone include:

- Gaskets

- ESD/EMI shielding

- Keypads & touch surfaces

- Gap fillers & vents

- Circuit connectors

- Wearable sensors and electrodes

- Medical device components

- Automotive wiring insulation

- Protective coatings for electronic

Final Verdict

Simply stated, silicone in its pure form is non-conductive. But it can be made conductive and utilised in a variety of applications. It is important to note that silicon and silicone are not the same term.

Silicon is a natural element that may conduct electricity under specific conditions. Silicone, on the other hand, is a synthetic material. Silicone is non-conductive and becomes conductive only when modified with fillers.

No matter whether you are using silicon or silicone, make sure to opt for a reliable supplier.

Hongju: A Trusted Partner For Custom Silicone Rubber Products

At Hongju Silicone, we have an experienced team to handle all your silicone rubber inquiries. Our low minimum order requirements combined with our ability to deliver custom rubber products in no time make us the best.

Get in touch with us today and get a quote for your bulk requirements.

FAQs

Q1. Does silicon conduct electricity?

Yes, silicon can conduct electricity, but it depends upon factors like temperature, impurities, and whether it is doped or not. Pure silicon is a semiconductor, meaning it conducts better than an insulator but not as well as metals.

Q2. Does silicon conduct electricity when solid?

Yes, when in a solid state, silicon can conduct electricity weakly. At room temperature, solid silicon allows minimal current flow. As a reason, solid silicon is used as a semiconductor rather than as a conductor.

Q3. Does silicon conduct electricity when molten?

Molten silicon conducts electricity better than solid silicon. When silicon is heated, the movement of free electrons increases, which allows the electric current to pass easily.

Q4. Is silicone safe around electrical wires?

Yes, silicone is generally considered safe around electrical wires. This is because silicone is an electrical insulator and resists heat.

However, one should only use electrical-grade silicone that is designed for wiring. Some silicone types may contain additives or release substances that could damage insulation.

Q5. Can electricity go through silicone?

No, pure silicone is an insulator. Thus, electricity cannot pass through silicone. However, by adding some fillers, you can make silicone conductive to some extent.