Silicone Rubber Die Cutting

Get customized silicone rubber products that suit your needs with our high-tech Rubber Die Cutting machinery

Silicone Rubber Die Cutting Services

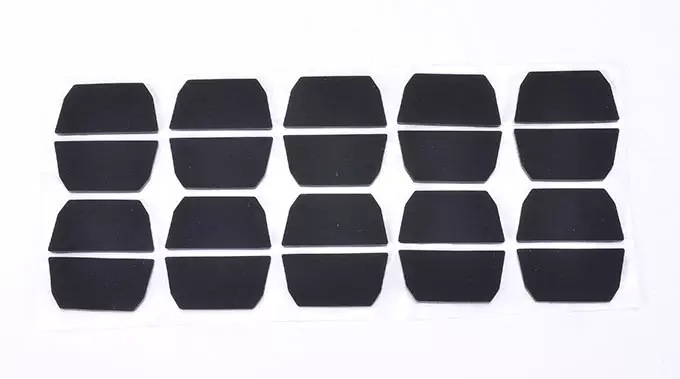

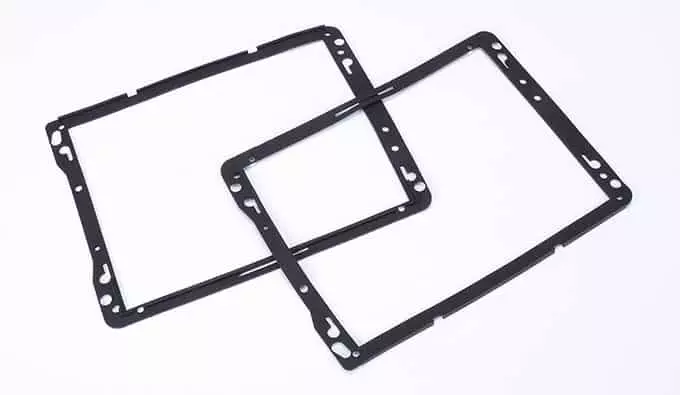

Hongju is a leading die-cut manufacturer and has captured both ODM and OEM market space in the span of 20 years. Our expert teams produce premium quality silicon products like rubber gaskets and seals, rubber feet, silicone rubber washers, etc. Also, we provide custom die-cutting services for our client’s projects with timely delivery and at the best prices. Hongju’s expert team and high-tech machinery can handle low to medium quantity product orders and provide rapid prototyping as well.

Features & Benefits of Custom Die Cutting

Custom Die cutting is a powerful yet simple technique that can create various complex rubber products. Its high precision and ability to produce intricate parts make it excellent for manufacturing silicone gaskets, seals, washers, etc. Some of these require specific materials, quantities, and designs that are otherwise difficult to manufacture with traditional methods. With minimum tolerances of +- 0.003 in. or (0.076 mm), it can produce more precise results than conventional machining and stamping methods. Higher precision means a better fit and less material waste, thus saving time and money with every product.

Considerations for Cutting Gaskets and Rubber Feet

- Material Selection

Softer materials result in concave edges upon deformation. For some applications, this property may be undesirable.

- Material Density

A high density means the material is stronger and more resilient, making it more difficult to cut. Less dense materials like soft rubber are easier to work and stretch, and material density is heavily dependent on applications.

- Material Thickness

Material thickness shares some similarities with density. Both properties result in additional strength. However, after a certain thickness, the material becomes incompatible with die-cutting.

- Geometry Design

Die-cutting has a lower limit of 2.5mm (0.1 inches). Material thinner than this is better suited to waterjet cutting. The final part will end up with some compression. It would be best to allow a tolerance of ± 0.5mm (0.02 inches) for all dimensions.

- Cutting Tolerances

As a general rule of thumb, softer materials will need more relaxed tolerances than sheet metal. For tighter tolerances, a solid steel tool or water jet cutting is recommended over steel rule cutting.

- Production Volume

Larger volume productions will result in lower costs per part.

- Packaging Logistics

Poorly packaged parts will result in inefficient shipping logistics. Optimizing the packaging method will result in significant cost savings.

Why Choose Hongju for Silicone Rubber Die Cutting?

Hongju’s high-tech facility and experienced teams have served clients all over the globe. We strive to provide you with premium quality silicon products using our state-of-the-art “Rubber Die Cutting” technology. Here at Hongju, our client’s success is our success.

- 24/7 customer support by our leading experts

- Fast turnaround on quotes

- Custom designs and Rapid prototyping

- 24-hour production

- ISO 9001:2015 certified

- Best prices and timely delivery

Contact Hongju for Custom Die Cut Rubber Products

We are here to assist you with your die-cut rubber projects. Our 24/7 customer support is at your service. Our expert guidance will surely help you succeed in your business. So what are you waiting for? Contact us NOW!