Conductive silicone strips are revolutionizing electrical connections, offering a flexible and durable alternative to traditional materials. But why is reliable conductivity so vital, and what makes these strips the go-to choice?

This post dives into their essential benefits, diverse applications, and guides you on selecting the perfect solution for your needs.

Why Conductivity is Necessary

Without electrical conductivity, the majority of the products we use in our lives will be rendered useless. So we will see the reasons why conductivity is a helpful phenomenon and how it benefits us in navigating our lives very easily.

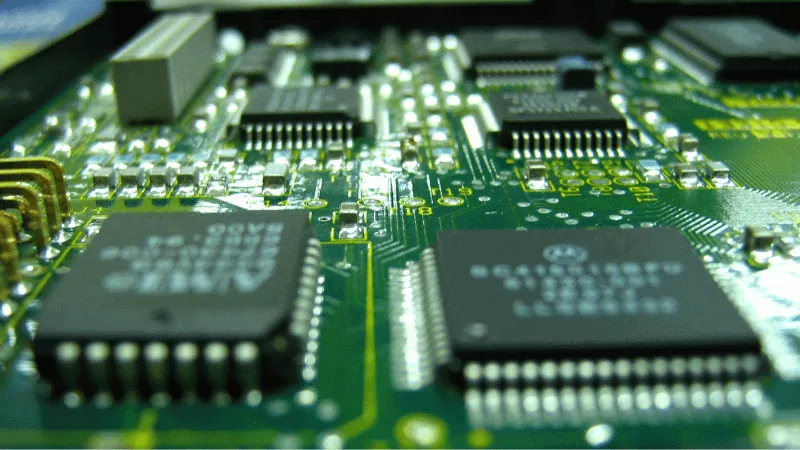

Connectivity for Electronics

Making and handling electronics with electrically conductive materials is crucial, as they need the electric current to pass through the required parts of the devices to function.

Transfer of Information

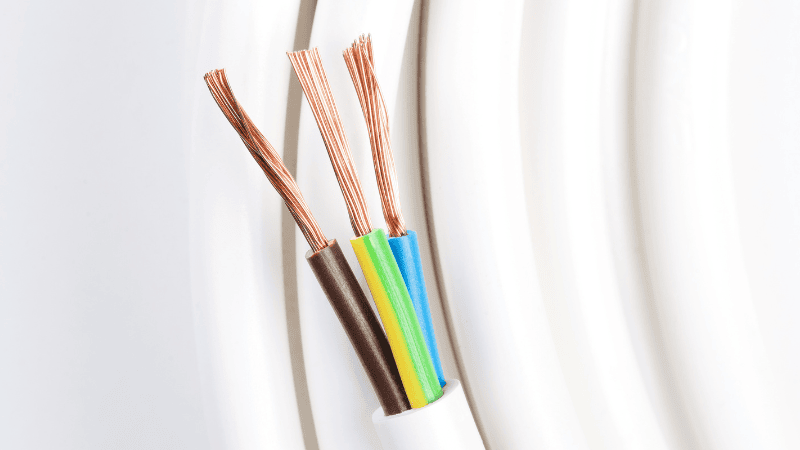

With internet/ethernet cables sitting deep in the oceans or on poles during snowfall, data is transferred with almost complete accuracy only because of the electrically conductive material in them.

Transmission of Energy

Conductive materials primarily help your energy provider install cables and wires that let the electric current pass through them easily. Therefore, your toasters and ovens don’t stop working midway through preparing an appetizing meal for you!

Additionally, conductive materials are commonly used in inverters, touchscreens, and medical devices. Seeing how crucial conductive materials are in our daily lives, we will explore the best conductive fixes for your tech needs!

What are Conductive Silicone Strips?

Although it is an insulator, silicone along with conductive components creates electrically conductive strips. These strips are then used to form any kind of machine or device you need.

Components of conductive silicone strips include substrates of silicone foam or silicone rubber and different metals like carbon, silver, copper, etc.

These substrates combine to form a product that is versatile in terms of electrical conductivity and possesses qualities like flexibility, resistance, longevity, and protection.

With all the mentioned qualities, conductive silicone strips become one of the most unique and impressive materials that can be used in any machine and device to upgrade its qualities and give it an edge over traditionally manufactured machines.

Benefits of Using Conductive Silicone Strips

Durable: Devices and machines designed with electrically conductive strips last a broad temperature range, different weathers, moisture, and natural stress.

Electric shavers and trimmers that are safe to be used in the shower are proof of silicone-made devices’ safe design.

Adaptable: These strips offer excellent conformability so can be used on uneven surfaces or to manufacture machines of all shapes and sizes.

Sleek and practical VR headsets and other wearable tech are a good way of testing silicone’s flexibility.

Protective: These electrically conductive adhesives provide a protective coating on surfaces exposed to unfavorable conditions while being completely conductive in areas where required.

Such strips can also function as sealants in various machine parts to protect them from harmful particles. Gaskets work to protect against leakages and using silicone in them offers a durable and safe option for the transfer of liquids.

Sustainable: They are long-lasting, lightweight, and eco-friendly which is their unique prospect as compared to other types of conductive materials.

Applications of Conductive Silicone Strips

Our engineers have successfully designed electrically conductive silicone strips that are used in industries like automotive, aerospace, tech, and healthcare.

Medical Devices

Medical devices, especially the ones coming in contact with patients, are made using electrically conductive silicone strips to ensure safety protocols and accuracy at the same time.

Wearable Tech

Tech items and gadgets like VR headsets also use conductive silicone strips for the smooth transmission of current. These are suitable in terms of thermal protection.

Consumer Electronics

Consumer goods like kitchenware and personal gadgets like, remote controls, joysticks, touchpads, touch screens, keyboards, electric shavers and trimmers, etc. make use of conductive silicone strips for safe and efficient flow of current where needed.

Adaptable/Flexible Circuits

Since many uneven surfaces need electrical conductivity, conductive silicone strips are useful in making flexible circuits for such needs.

Automotive Parts

Electrically conductive silicone strips are commonly used in control panels and other components in automobiles ensuring safe coverage on uneven surfaces along with durability and efficiency.

The aerospace industry also uses electrically conductive material for finishings.

Electrically Conductive Adhesives

Electrically conductive rubber are most often used in electronics, automotive, aerospace, medical, and tech industries serving the role of adhesives and electric conductors at the same time.

They can also be used as adhesive sheets in various applications. Electrically conductive adhesives do not require high heat for adhesion and are used commonly in various industrial applications.

Low Surface Energy Materials

Silicone being one of the low surface energy materials is also used in applications where less adhesion is required. Due to this property of non-adhesion, it can be easily used in applications where it works as a repellent.

Some applications include parts in the automotive and aerospace industries that prevent friction and ice formation.

EMI Shielding

Electromagnetic interference shielding is important to keep unnecessary electromagnetic radiation away from electronics. If not taken care of, electromagnetic interference can cause serious harm to our devices.

EMI shielding makes use of conductive material to absorb or channel unnecessary electromagnetic radiation away from sensitive electronic systems.

Electromagnetic interference can be created by using electrically conductive adhesives on surfaces required to be kept safe.

Comparison with Other Conductive Materials

| Features/Properties | Conductive Silicone Strips | Conductive Rubber | Conductive Foam | Conductive Adhesive Tape | Copper Strips |

|---|---|---|---|---|---|

| Conductivity | Good | Moderate | Low | High | Very High |

| Flexibility | High | Moderate | Low | Low | Low |

| Durability | High | High | Moderate | Moderate | High |

| Temperature Range | -50 to +200°C | -30 to +150°C | -20 to +80°C | -20 to +120°C | -40 to +200°C |

| Cost | Moderate | Low | Low | Moderate | High |

| Application Ease | Easy | Moderate | Easy | Moderate | Difficult |

| Chemical Resistance | Good | Moderate | Moderate | Low | Moderate |

| UV Resistance | Excellent | Good | Moderate | Moderate | Good |

| Environmental Impact | Low | Moderate | Moderate | High | Moderate |

How to Choose the Right Conductive Strips for Your Need?

To answer your question, the following are the criteria to asses which electrically conductive strips are the best fit for your needs.

Requisites: Start by thinking about the need for the conductive strips. What do you need from the strips, durability, adaptability, protection, better conductivity, or a mix of all of those?

Conductivity: Identify the level of electrical conductivity that you require. There are different conductive silicone strips designed with varying levels of conductive substrates for all kinds of applications.

Suitability: Think of the material that will be in contact with the conductive strips. Since without compatibility between both surfaces, damage to products and failure in achieving the desired results is possible, checking this is crucial.

The safest option in this case will be silicone as it is one of the elements that are compatible with all kinds of materials.

Shape & Size: Know the required shape and size of the finished product. Identify if there are any unique shapes that require bending and folding the conductive strips.

In that case, conductive silicone strips that offer excellent conformability will be the better option.

Setting: Know the environment in which the product will be manufactured and used. Find out if the finished products will be exposed to moisture, heat, or unfavorable environmental conditions beforehand.

Consequently, conductive silicone strips that are proven to offer thermal conductivity can be considered.

Budget: Think about the budget you have for your product. For a budget-friendly option, conductive silicone strips are the go-to choice for the majority.

Installation and Maintenance Tips

Conductive silicone strips are essential in various industries for their excellent conductivity, flexibility, and durability. Proper installation and maintenance are crucial for optimizing their performance and lifespan.

Here are some tips to guide you.

Guidelines for effective installation

Before applying the conductive silicone strips, follow the given steps to ensure smooth application:

Prep the Surface: Start by cleaning the surface where the conductive silicone strips will be installed. Clean the surface with a cleaning agent to remove dust, stickiness, and moisture.

Only a clean surface will guarantee strong bonding and adhesion.

Prep the Conductive Strips: Measure the area of application and cut the conductive strips accordingly. Make sure to clean the conductive strips as well with a recommended cleaning agent.

Adhesives: Find adhesives that are compatible with both the surface and conductive silicone strips. Many sealing strips come with a pre-applied adhesive.

You can easily activate it by peeling off the protective liner and pressing the strip into place. If not, a variety of adhesive options are available to meet your specific needs.

Application: Apply the adhesive on the conductive strips and place them gently on the prepped surface. Apply pressure uniformly for the duration recommended for complete adhesion.

Setting Time: Let the conductive silicone strips dry on the surface for the time that is given for the respective bonding agent and conductive strips.

Remember to not move the product until the strips have completely bonded and cured.

Maintenance Tips for Longevity

You can increase the durability of your conductive silicone strips by ensuring the following steps.

Periodic Checks: Check for signs of damage regularly. Notice any removal of adhesive, or breakage in the strips and do the needful to secure the exposed area on the machine/devices.

Cleaning: Clean with a recommended cleaning agent at regular intervals. Regular cleaning helps greatly in extending the lifespan of your products.

Also, make sure that you are not overcleaning the strips with harsh chemicals as it will significantly reduce their durability.

Documentation: Keep a record of checks and maintenance to ensure transparency for warranty claims.

Documentation will also help you track the performance in terms of durability especially where weather conditions are rough.

Conclusion

Conductive silicone strips have become essential in modern electronics, offering a reliable, flexible, and durable way to ensure stable conductivity across countless applications.

Whether you’re designing sensitive electronic components or seeking safer, longer-lasting conductive materials, these strips deliver excellent performance where precision truly matters.

Hongju is the Go-To Choice For Conductive Silicone Strips

Hongju Silicone provides durable, comfortable, and authentic ready-to-use components to solve your tech challenges instantly.

Leverage our 20+ years of expert craftsmanship, ultra-fast 3-5 day prototyping, and flexible low MOQs to get to market faster.

Contact our experts today for a superior solution!

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

FAQs

1. How does this differ from a standard rubber gasket?

It performs a critical dual function: it seals out moisture and dust like a normal gasket while simultaneously blocking electromagnetic interference to protect sensitive circuits.

2. Why is EMI shielding actually necessary for my device?

Without it, your device can emit signals that disrupt other equipment or be corrupted by external noise, leading to data errors, malfunctions, or compliance failure.

3. Will the conductivity degrade over time?

High-quality strips use stable conductive fillers (like nickel-graphite) that maintain their shielding effectiveness for years, even under constant compression and temperature cycling.