Today I’m going to provide you with a complete understanding of acrylics and their wide range of applications.

Besides, I’ll delve into some compelling reasons why acrylics are the go-to material for customized production where you want to fuse creativity with durability and sustainability.

Let’s dive in!

Understanding Acrylic Plastics

The scientific name of Acrylic Plastics is polymethyl methacrylate (PMMA). They are quite a remarkable class of materials that you can use in everyday life applications and industries.

The reason behind the widespread use of acrylic plastic is its exceptional transparency and glass-like clarity.

The material is similar to polycarbonate in that it is suitable for use as an impact-resistant alternative to glass (particularly when the high impact strength of PC is not required).

Its optimal clarity isn’t the only feature that makes it popular, another thing about acrylic sheets is their durability. They boast high resistance to shattering and weathering.

Once the durability factor is combined with the lightweight nature of this material, it allows manufacturers to create a wide variety of ideas ranging from protective barriers to outdoor signage and furniture, and even eyeglass lenses.

The versatile nature of acrylic plastics lets manufacturers mold them into diverse shapes and sizes. It’s quite easy to create innovative solutions and intricate designs with these specific materials.

Optical Clarity and Aesthetics of Acrylics for Plastic

The optical clarity and aesthetics of acrylic sheets make them an attractive material for a wide variety of uses. Whether you want to get a sleek modern look or thinking about getting a crystal clear view, acrylics got you covered.

In the world of design and everyday objects, acrylics have solidified their place because of their ability to combine form and function in an aesthetically appealing package.

Let’s uncover more details below.

1. Exceptional Transparency

PMMA boasts top-level transparency or glass-like clarity. When you look through them, you can get a virtually distortion-free view of objects on the other side.

This property of acrylics makes them valuable in applications where visual quality matters the most. Thereby, they are used for the production of protective barriers, displays, and picture frames.

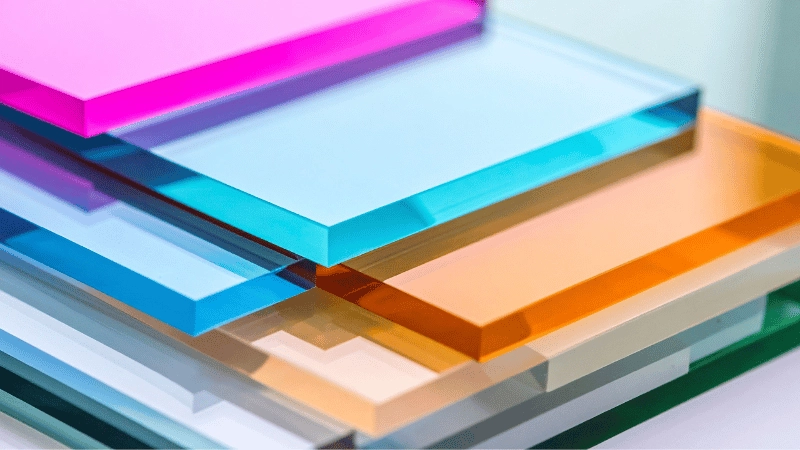

2. Vivid Colors and Gloss

It’s really easy to tint Acrylics. These days, you can find acrylics in a wide variety of colors and glosses. They have a natural gloss that combines with vivid color making them super appealing.

These properties of acrylics make them ideally suited for the creation of signage, art pieces, and even many outdoor applications.

3. UV Resistance

Another plus point of Acrylic plastics is that they have a strong ability to resist yellowing or fading, no matter how long they are exposed to sunlight or UV radiation. They maintain their shade and gloss, even with prolonged exposure.

4. Sleek and Modern Appearance

They are widely used in interior design because of their sleek look and contemporary appeal. Lighting fixtures, decorative items, and furniture often feature acrylics for their timeless look, impact resistance, and lightweight nature.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Easy Fabrication and Molding

The aesthetic appeal and optical clarity of acrylics aren’t the only reasons why select acrylics for plastic fabrication. Another major reason is the ease of fabrication and molding with Acrylic Plastics.

Working with this material is a breeze, let’s find out more.

Thermoforming Flexibility

When you need to deliver custom design solutions to your clients, acrylics are indeed the suitable choice. They are super adaptable in thermoforming.

During the process, the manufacturer can heat the acrylic sheet until it becomes pliable and then turn it into the desired form or shape.

Whether your project involves the creation of custom-shaped products or intricate sculptures, acrylic will be molded with precision and perfection.

Simplicity in Cutting

When it comes to cutting the acrylic sheet, you won’t face any struggle. The best part of cutting is that you won’t need any specialized tools for cutting.

Commonly used tools like saw routers or laser cutters are useful during the acrylic cutting process.

Drilling and Machining

Another plus of Acrylic is its ease of drilling and machining. When it comes to adding details and patterns in your design, you opt for drilling or machines.

However, you can easily do drilling or machining because acrylics don’t crack or splinter. You will get clean and precise results every time.

Joining Methods

Acrylics offer great flexibility when it comes to joining. You can use mechanical fasteners such as bolts or screws during assembly of acrylic structures.

Acrylic adhesive or solvent cement creates a strong chemical bond by fusing the pieces together. This flexibility in joining method allows you to choose a method as per your project needs.

Applications of Acrylics in Plastic Fabrication

In everyday life, you can see various applications of acrylics in Plastic Fabrication. Let’s uncover them one by one.

Displays and Signage: Acrylics let color pop and are UV-resistant materials, so commonly they make an excellent choice for signage and displays.

Art and Sculptures: When an artist wants to unlock his sculpting superpower, acrylics are certainly the best creative canvas to start your project with.

This ideal material can be molded into pretty much any shape. That’s why today you can find tons of mind-blowing acrylic sculptures in galleries globally.

Funky Furniture: The glossy finish and colorful appearance of acrylics make them an excellent choice for crafting funky furniture such as chairs, tables, shelves, and whatnot.

Aquariums: The Glass-like clarity feature of acrylics is why they are usually turned into beautiful aquariums.

Lighting Fixtures: Acrylics can scatter light magically, thereby they are used to create lighting fixtures and decorative items.

Protective Barriers: As you can see clearly through rigid acrylic plastic, they are usually transformed into proactive barriers in offices, taxis, and offices.

Understanding the Difference: Acrylic vs. Plastic

Acrylic is a type of plastic but it stands out for its rigidity, UV resistance, and clarity. Plastic is a very broad category that includes various types. Each type has some distinctive properties.

Although, they seem similar here are some points of difference between Acrylic and Plastic:

| Feature/Aspect | Acrylic (PMMA) | Polystyrene (PS) | Polyethylene (PE) | Polyvinyl Chloride (PVC) |

|---|---|---|---|---|

| Transparency | Very high: Crystal clear | Varies: Can be clear | Low: Typically opaque | Varies: Can be clear to opaque |

| UV Resistance | Good | Moderate | Low | Good |

| Impact Resistance | Moderate | Low | High | Moderate |

| Durability | High | Moderate | High | High |

| Rigidity | Rigid | Rigid | Flexible to semi-rigid | Rigid to flexible |

| Chemical Resistance | Moderate | Low | High | Good |

| Heat Resistance | Moderate | Low | Low to moderate | Moderate |

| Cost | Generally higher | Low | Low to moderate | Low to moderate |

| Common Uses | Signs, optical devices, aquariums | Packaging, disposables | Bags, bottles, toys | Pipes, cable insulation |

Acrylic (PMMA) distinctly sets itself apart from Polystyrene (PS), Polyethylene (PE), and Polyvinyl Chloride (PVC).

Its superior transparency, comparable to that of glass, makes it a prime choice for applications demanding visual clarity, such as aquariums, optical devices, and signage.

Additionally, its commendable UV resistance ensures longevity, especially when used in outdoor settings.

While other plastics have their respective strengths, Acrylic’s combination of aesthetics, UV resilience, and rigidity positions it as a favored material in applications that demand both beauty and durability.

Environmental Impact and Sustainability

Before you start acrylic Fabrication, it’s time to understand how this material impacts the environment.

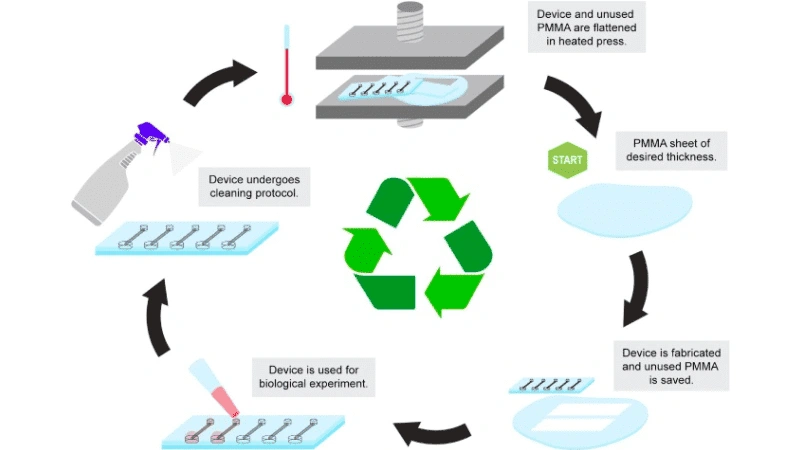

1. Recyclability

The environmental impact of this material is quite low because it’s recyclable. Once you are done with a display, sign, or other acrylic items.

You can send them to a recycling center whether they will melt down and turn into fresh acrylic sheets. It reduces waste in landfills.

2. Eco-Friendly Production

If you like a go-green approach during production, acrylics can offer you peace of mind. It’s because when this material is made, it won’t emit dangerous chemicals into the water or air.

Besides, acrylic consumes less energy than other plastics. So, basically, you will be reducing your carbon footprint when going for acrylic fabrication.

3. Durability for the Win

Don’t overlook the durability feature of acrylics. You can use them for a long time, which means they won’t require quick replacement. As they are impact-resistant, they require fewer replacements which means less waste.

Don’t you think it is a win-win material for a better, more sustainable planet?

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Acrylic plastic offers an impressive mix of durability, tensile strength, clarity, and vibrant aesthetics, making it ideal for countless fabrication needs. Beyond its design flexibility, acrylic also supports energy-efficient production and recyclability, helping reduce environmental impact.

Choosing acrylic means choosing a material that blends creativity, performance, and sustainability, an excellent option for a smarter, eco-conscious future.

Why go to Hongju for your Acrylic Plastics Needs?

Hongju emerges as a beacon in the acrylic plastics industry, blending unmatched know-how with consistent quality results. Leveraging advanced tools, adept professionals, and commitment to exactitude, we deliver premium acrylic solutions every time.

Partnering with Hongju ensures you benefit from unparalleled transparency, durability, and tailored services in all your acrylic endeavors.

FAQs

1. Why is acrylic a popular material for plastic fabrication?

Acrylic is lightweight, durable, and offers exceptional clarity, making it ideal for displays, signage, lighting, and protective covers.

2. Is acrylic stronger than glass?

Yes. Acrylic is up to 17 times more impact-resistant than glass while being much lighter and safer to use.

3. Can acrylic be easily shaped or customized?

Absolutely. Acrylic can be cut, laser-engraved, thermoformed, polished, and bonded into nearly any shape with excellent precision.

4. Does acrylic maintain clarity over time?

Yes. High-quality acrylic resists yellowing, UV damage, and scratches, keeping its transparency for years even in outdoor environments.