Technology is fast-paced, and it is critical to stay ahead. As a business owner, incorporating silicon circuit boards in your electronic devices provide an edge over your competitors. Silicon circuit boards provide a sturdy foundation for electronic circuits. With their properties and versatility, you can use them to incorporate reliable and efficient technology into your products.

This article thoroughly explores silicon circuit boards, including the benefits, types, and how to choose one for your business.

What is Silicon Circuit Board?

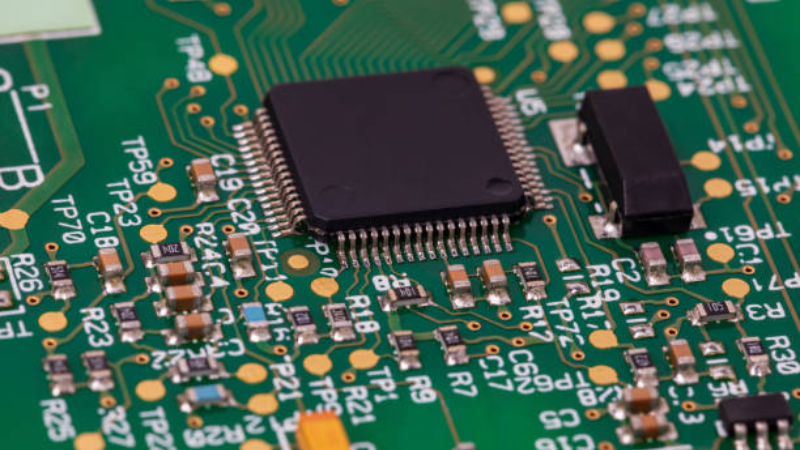

A silicon circuit board (SiCB) has silicone as its base material. This board is also a printed circuit board (PCB), serving as a platform for interconnecting electronic components and enabling the flow of electric signals within an electronic device.

What is Silicon Used for Circuit Boards?

Silicon is a semiconductor with excellent electrical properties like conductivity and low resistance. Consequently, this material allows efficient signal transmission and power delivery in a circuit board. Other silicon properties that make it ideal for a circuit board include its high temperature and weather resistance, durability, and stability.

Silicon Circuit Board Types

There are different types of silicon circuit boards (SiCBs). These boards differ in complexity and signal strength. Silicone circuit board types include the following;

Single-Sided

Single-sided silicon circuit boards are the most basic type. This board has a single layer of silicone substrate with components on one side. The components of this board are soldered to the top side, while the conductor tracks and interconnecting components are on the bottom.

Single-sided circuit boards are often used for simple electronic devices with less complex circuitry and fewer components.

Double-Sided

Double-sided circuit boards have more space for components and traces since the components and conductor tracks are added on both sides of the silicon substrate. The top and bottom layers of the board are connected through vias (plated-through holes) to allow electrical signals to pass between the layers.

Double-sided circuit boards are versatile and used in various applications because they enable more complex circuit designs.

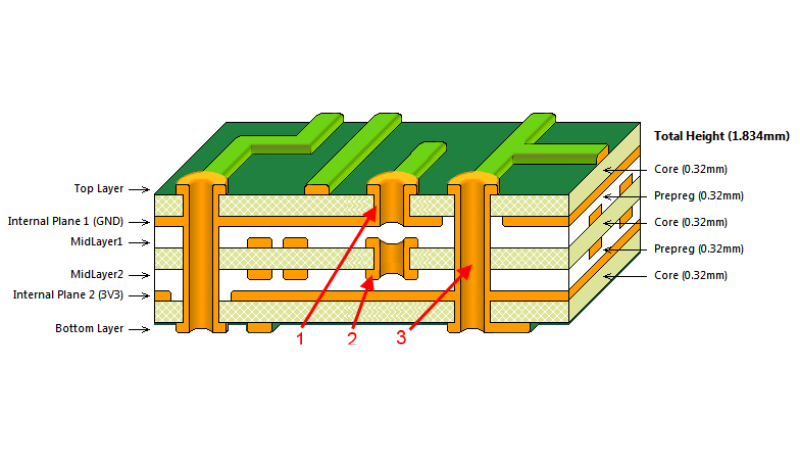

Multi-Layered

Multi-layered circuit boards have multiple layers of silicon substrate stacked on each other. Like double-sided circuit boards, the layers are connected through vias to allow the free flow of electrical signals between the layers. The external layers of this board host the components and traces, while the internal layers are used to route power.

Multi-layered circuit boards have a higher component density and improved signal strength. This type of board is also used in advanced electronics like smartphones and network switches, where complex circuitry is required.

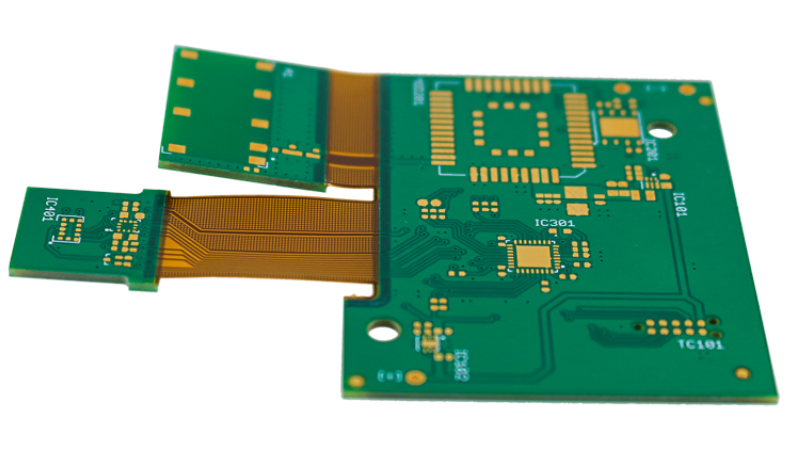

Rigid-Flex

Rigid-flex circuit boards combine rigid boards and flexible circuits. The rigid section is made from silicon, while the flexible section is made of a thin, flexible polymer substrate. This circuit board allows the integration of rigid and flexible components onto the boards. Therefore, the board can easily bend, twist, or fold.

Rigid-flex boards are suitable for applications with space constraints and dynamic movements. Wearable devices, automotive electronics, and aerospace systems make use of a rigid-flex circuit board

9 Benefits of the Silicon Circuit Board

1. Reliability

Due to the exceptional properties of silicon, including stability and durability, silicon circuit boards are known for their reliability. The boards can withstand harsh environmental conditions and temperature fluctuations without compromising quality. Consequently, electronic devices built on silicon circuit boards will consistently meet your customers’ demands.

2. Miniaturization

Silicon circuit boards have a compact size that allows the addition of more components, resulting in smaller and sleeker designs. Because space is limited in consumer electronics and aerospace industries, the miniaturization of electronic devices comes in handy.

3. High-performance

Silicon has a low resistance and excellent conductivity, contributing to the high performance of silicon circuit boards. Consequently, the boards allow efficient power delivery and faster signal transmission for the improved overall performance of an electronic device.

4. Cost-effectiveness

Over the years, silicon circuit boards’ manufacturing process has improved, leading to more efficient production. Because these boards minimize repair and replacement costs, they save your business money.

5. Compatibility

Silicone circuit boards are compatible with several electronic components. Consequently, you can seamlessly integrate different modules and systems on the board, adapting them to your needs. Whether your business deals with simple or complex electronic devices, silicone circuit boards are versatile enough to meet your needs.

6. Durability

Silicon circuit boards are durable, increasing the lifespan of electronic devices. The board has an efficient construction that improves resistance to wear and tear. Incorporating silicon circuit boards in your product reduces the frequency of replacements, providing your customers with a long-lasting solution.

7. Eco-friendliness

Silicon circuit boards are eco-friendly due to their longevity and reliability. Consequently, these boards produce minimal electronic waste, making them an eco-friendly business option.

8. Customization

Manufacturers like Hongju can customize silicone circuit boards’ design, layout, and functionality to meet your business’s specific requirements. Consequently, your business can stand out from the competition with unique electronic devices catering to your customers’ needs.

9. Reduced time-to-market

Silicon circuit boards are compatible with rapid prototyping and assembly processes. This accelerates product development, reducing the time-to-market of your product.

Application of silicone circuit board

Silicon circuit boards enable technological advancements across several industries, including electronics, aerospace, and medicine. This is due to the exceptional properties of silicon circuit boards, including high performance, compact design, and customization options.

Electronics and semiconductors

Silicon circuit boards produce compact and portable consumer electronics like smartphones, tablets, laptops, and televisions. The circuit boards enable the functioning of various electronic components like memory chips, microprocessors, and communication modules in these devices.

Aerospace and defense

Silicon circuit boards are used in the aerospace and defense industry for radar, avionics, and flight control systems. The boards are also used in navigation systems and satellite communications. The aerospace and defense industry uses silicon circuit boards to withstand harsh environmental conditions, including temperature fluctuations, electromagnetic interference, and vibrations.

Industrial control systems

Automation and process control systems are industrial control systems that use silicon circuit boards. These circuit boards provide connectivity, signal processing, and data transfer to facilitate the control of industrial machinery.

Medical devices

Laboratory instruments, imaging devices, diagnostic equipment and implantable devices all use silicon circuit boards. The customization and miniaturization of the circuit boards make them ideal for medical devices requiring precise measurements, connectivity, and data processing.

High-performance computing

Silicon circuit boards provide heat dissipation, optimal performance and power management in high-performance computing systems. Consequently, systems using these boards have better computational power, memory capacity, and data transfer capabilities.

How to Choose Silicone Circuit Board

Before choosing a silicone circuit board, it is essential to consider several factors to ensure the board meets your business need and contributes to the success of your electronic device. Factors to consider before choosing a silicone circuit board include the following;

Application

Your silicone circuit board should meet your application’s requirements for maximum performance. Consider the prevailing conditions the board will be subjected to, including temperature range, chemical exposure, vibration, and humidity. Depending on the specific requirements of your application, choose a silicone circuit board that can withstand these conditions and perform optimally.

Components

Consider the components’ size, electrical specifications, and pin configuration to be integrated into the board. The board should have the necessary connectors, interfaces, and mounting holes for your application.

Reliability

Besides compatibility with your application, the silicon board must be reliable. Before choosing a circuit board, consider if it has undergone rigorous testing. Choosing circuit boards that adhere to industry standards is best, ensuring minimal failure risk in your application.

Cost

You can consider prices across different suppliers and the value they provide before choosing a silicon circuit board. Nevertheless, it is best to remember that a lower-cost circuit board does not guarantee reliability and performance. Hongju is an excellent manufacturer with reasonable prices and no compromise on quality.

Testing and Inspection of Silicon Circuit Boards

Testing and inspection of silicon circuit boards help verify the board’s quality, functionality, and reliability. You can detect defects and issues early in the production cycle, minimizing waste and downtime. Testing methods for silicon circuit boards include the following;

In-circuit testing

In-circuit testing verifies the electrical integrity of silicon circuit boards. This testing method involves using specialized test equipment to check the functionality of individual components like resistors and capacitors. Through this method, you can identify incorrectly placed and unsoldered electrical components.

Functionality testing

Functionality testing checks the functionality and overall performance of the silicon circuit board. This test ensures that the board is performing as expected. The test procedures may simulate real-world conditions to assess the board’s performance and reliability.

Visual inspection

Visual inspection examines the silicon circuit board to check for physical defects. These defects include misalignment of components, foreign objects, soldering issues, and other visible anomalies. You can check the board’s quality and reliability through a magnified visual examination or an automated system.

X-ray inspection

X-ray inspection is used to inspect the internal structure of the silicone circuit boards. This testing method allows you to check for hidden defects. It is a non-destructive method of checking the board’s internal connections and integrity.

Ultrasonic inspection

Ultrasonic inspection is also a non-destructive testing method for assessing the quality of the solder joints and bonds between the silicon substrate and components. This test method uses high-frequency sound waves to detect anomalies and inconsistencies in the board’s internal structure.

Q&A: Common Questions about silicone circuit boards

Q: What is the difference between a Silicon Circuit Board and PCB?

Silicon circuit boards look like printed circuit boards (PCBs). However, silicon boards have silicon, a non-conductive element, as their substrate material. Electrical components are fabricated directly on the substrate using different techniques.

On the other hand, PCBs have substrates from a non-conductive material like fiberglass-reinforced epoxy or a flexible polymer. The choice of substrate material usually depends on the application requirements.

Q: Why is Silicon so Good for Electronics?

Silicon is a semiconductor. That is, it offers both conductive and insulating properties. These properties allow the material to regulate the flow of electric current. Silicon is often used for several electronics besides circuit boards. It is also used for manufacturing transistors and diodes.

Another reason why silicon is suitable for electronics is that it is the second most abundant element. Therefore, it is abundant and cost-effective. It also possesses thermal stability properties. The material can withstand elevated temperatures without significant degradation.

Q: How do Silicon Circuit Boards Compare to Other Types of Circuit Boards?

Silicon circuit boards have several advantages, like metal core (MCPCBs), ceramic, and high-density interconnect (HDI) circuit boards. Silicon circuit boards have improved signal integrity, thermal management, and high-speed capabilities.

In addition, silicon circuit boards are durable and manufactured in large volumes to save costs. This type of circuit board also facilitates the integration of multiple components and functionalities on a single board.

Conclusion

Silicone circuit boards are a versatile component of electronic devices. Because there are different types, they can match the complexity of your electronics. Furthermore, all silicon circuit boards offer several benefits, including cost-effectiveness, miniaturization, longevity, and co-friendliness.

However, consider your application, components, and board reliability before choosing a silicon board for your business. The tests discussed in this article can help you evaluate the reliability of silicon circuit boards.

Discover the Perfect Solution for Your Business with Silicon Circuit Boards

Partnering with a reputable supplier ensures you get your business’s best silicon circuit boards. Hongju manufactures high-quality silicone rubber products that incorporate silicon circuit boards. Partnering with us means you get access to our high-grade product range.